Airports

Challenge

Taxiway slabs at a major international hub had settled by up to 50mm due to subgrade erosion and dynamic loading. The uneven surface created "steps" at joints, posing a safety risk to aircraft landing gear and ground vehicles.

Solution

Geobear utilized a specially selected structural geopolymer (Type II) to inject beneath 392m² of pavement. The process restored slab levels to tolerance, achieved >1 MPa compressive strength, and was completed during restricted night shifts with zero operational disruption.

Up to 50 mm of settlement corrected to 0 mm

design life validated under cyclic aircraft loading

lower CO₂ vs. cementitious grouting

The project presented three major challenges:

Variable settlement conditions: Four slab blocks across the taxiway had different magnitudes and directions of settlement, ranging from 5 mm to 50 mm. The settlement was concentrated at slab edges where sealant failure had allowed water ingress. Combined with dynamic aircraft wheel loading, this had led to sub-base pumping and erosion.

Operational constraints: Works had to be completed without disrupting airfield operations. The method needed to fit within short night possessions, with slabs reopened to aircraft traffic the following morning.

Design requirements: The client specified that the material must:

Geobear’s engineering team carried out a detailed analysis of three different geopolymer formulations to determine the optimum balance between lifting efficiency, compressive strength, and design life.

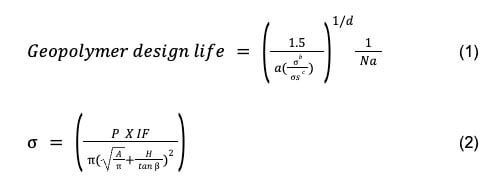

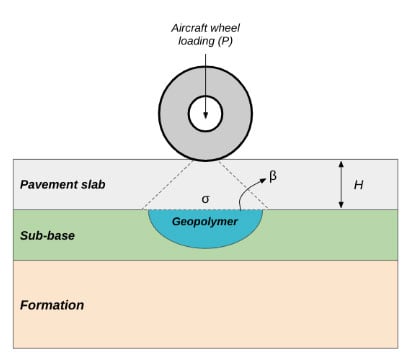

The design life of the geopolymer was calculated using Geobear Design Life Model (GDL), see Equation 1, which was based on extensive laboratory cyclic loading testing and bespoke to Geobear’s geopolymers. The use of this model requires estimating the vertical stress generated on the geopolymer due to aircraft loading and was done using a Pyramid Load Distribution (PLD) simplified method, as shown in Equation 2, along with inputs from Jacobs and HAL related to aircraft loading and loading frequency. From the calculations it was found that Type III geopolymers had a design life that exceeded 60 years and then followed by 27 years and 12 years for Type II and Type I, respectively.

Where,

A: Wheel contact patch.

a,b,c,d: model coefficients.

: applied vertical stress on the geopolymer.

s: geopolymer compressive strength.

Na: number of applied loading cycles.

P: aircraft wheel loading.

IF: Impact factor to account for dynamic nature of the wheel load, typical value of 1.5 for taxiing aircrafts.

H: slab thickness.

Based on the analysis, it was concluded that Type II geopolymer would provide the most cost-effective and optimum design as it would be able to satisfy all the clients requirements along with the high lift efficiency. Type I geopolymer would provide the maximum lift efficiency, but cannot provide sufficient compressive strength and design life.

On the other hand, Type III geopolymer would have the maximum compressive strength and design life but with low lifting efficiency. Therefore, Type II seems to provide a well-balanced design that provides sufficient compressive strength and design life while maintaining a high level of lift efficiency, hence it was selected for this application.

The project successfully re-leveled and stabilized all affected slabs:

Pre injection slab

Post injection

Get in touch with our expert team today and discover how Geobear can extend the life of your critical infrastructure assets.