Structural support without the heavy machinery

When you need to increase the load-bearing capacity of the ground—for new machinery, a mezzanine floor, or to rescue a failing foundation—traditional piling is often too disruptive. It requires large rigs, creates damaging vibrations, and demands that you clear your facility.

Geobear offers a smart alternative: Geopolymer Pillars.

Also known as PowerPiles, these are structural polymer columns installed directly through the floor slab. They act as "mini-piles" or semi-rigid inclusions, transferring loads to deeper, more stable soil strata without the need for excavation or heavy plant.

What are geopolymer pillars?

Geopolymer Pillars are a patented technology designed to strengthen very weak ground and support heavy structural loads.

Unlike concrete piles that are poured or driven, our pillars are expanded into place:

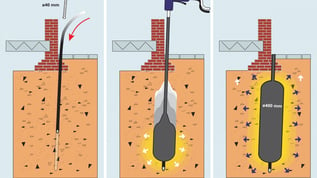

1. Insertion: We drill a small hole (approx. 50mm) through the existing floor slab. A specialized geotextile casing is inserted into the ground to the required depth (up to 6m+).

2. Injection: We inject our high-density structural geopolymer resin into the casing.

3. Expansion: The resin expands inside the casing, filling it completely. As the pillar widens (up to 400mm diameter), it compacts the surrounding soil via skin friction and end bearing.

4. Curing: The pillar cures to full strength in minutes, creating a solid, composite structural element capable of supporting significant vertical loads.

Why use geopolymer pillars in the UAE?

The UAE's construction environment often involves retrofitting existing warehouses or factories built on loose sandy soils or reclaimed land. Geopolymer Pillars are the ideal solution for these constraints.

Restricted Access Capable:We can install pillars inside operational factories, basements, or tight warehouse aisles. Our equipment is handheld and portable, fitting through standard doors.

No Vibration:Traditional pile driving causes vibrations that can damage sensitive machinery or nearby structures. Our process is vibration-free.

Clean & Dust-Free:There is no augering of soil (spoil removal) and no concrete splatters. It is safe for food production and clean-room environments.

Speed:<7strong>We can install multiple pillars in a single shift. There is no 28-day cure time; the pillars can be loaded immediately.

Applications

Survey and supporting new heavy machinery

If you are installing a new press, CNC machine, or generator, the existing slab may not take the weight. We install pillars grid-pattern under the machine base to transfer the load deep into the ground.

Mezzanine floor foundations

Adding a mezzanine increases the point loads on your floor. We install pillars directly beneath the proposed column locations to support the new structure.

Subsidence repair in weak soil

Where standard ground injection is not enough (e.g., in peat or extremely soft clay), pillars provide a direct structural transfer of load to competent ground layers.

Building extensions

Strengthening the ground adjacent to an existing building to support new walls or columns without underpinning.

Comparison: geopolymer pillars vs. traditional mini-piling

| Feature | Geobear Geopolymer Pillars | Traditional Mini-Piling |

|---|---|---|

| Hole Size | 50mm (Drilled through slab) | 150mm - 300mm+ (Requires core drilling) |

| Excavation | None. No spoil to remove. | Yes. Augered soil creates mess/spoil. |

| Cure Time | Immediate. Load in 15 mins. | Slow. Concrete requires days/weeks. |

| Vibration | Zero. Safe for sensitive sites. | High/Moderate. Can damage assets. |

| Equipment | Handheld. Fits through doors. | Rig-based. Requires headroom/access. |

Support your heaviest loads

Need to increase your floor's load capacity? Contact our engineering team to design a bespoke geopolymer pillar solution for your project.

FAQ