Challenge

Void formation beneath 58 slabs in a busy airport apron risked future settlement and operational disruption — traditional repairs would have required excavation, downtime, and significant cost.

Solution

Geobear proactively injected geopolymers beneath each slab to fill voids, prevent settlement, and maintain full operations — completing the 12-day programme ahead of schedule in just 11.

completion — 1 day ahead of schedule

slabs reopened immediately after treatment

Slabs stabilised using 1.5 m injection grid

At a major UK airport, condition surveys using Ground Penetrating Radar (GPR) and core sampling revealed the presence of voids and inconsistent soils beneath slabs in the East Apron and taxiway area.

Although the slabs had not yet experienced significant movement, the airport operator recognised that untreated voids could lead to uneven settlement, steps between slabs, and operational hazards for aircraft taxiing and parking. A decision was taken to act proactively, preventing future disruption by stabilising the slabs in advance.

The main challenge was future-proofing the apron area. If left untreated, voids beneath slabs would have allowed differential settlement to develop under aircraft wheel loading, causing lips between slabs and uneven surfaces. This would have created safety hazards, operational delays, and potentially forced slab reconstruction.

The client faced a clear choice:

Do nothing — avoiding upfront costs, but risking future disruption, higher remediation costs, and even penalties from airlines due to operational delays.

Take proactive action — addressing the voids before they led to failures, ensuring operational continuity.

The proactive approach was chosen, requiring a method that could be installed quickly, without excavation or downtime, and with long-term assurance of slab stability.

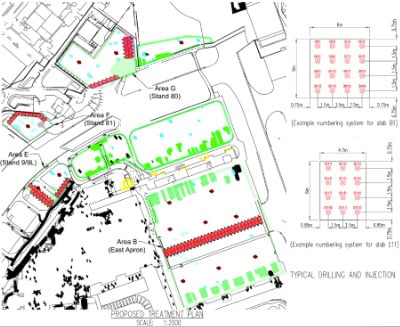

Geobear designed and delivered a comprehensive void-filling programme using expansive geopolymer injection:

The geopolymer resin provided immediate stabilisation, displacing any water present and expanding to occupy voids fully. Its inert, closed-cell structure ensured no risk of leachate or contamination in a sensitive airport environment.

Treatment plan

The project delivered measurable benefits:

Get in touch with our expert team today and discover how Geobear can extend the life of your critical infrastructure assets.