Challenge

Heathrow Terminal 3’s foundation system couldn’t support the increased loads from a planned vertical expansion — traditional foundation widening would have required excavation, disruption, and costly operational downtime.

Solution

Geobear increased foundation bearing capacity using precision geopolymer injection, achieving up to 100% strength gain four times faster than conventional methods, with zero disruption to terminal operations.

faster than traditional excavation-based methods

reduction in CO₂ footprint

Foundation capacity increase

At London Heathrow Airport Terminal 3, the client sought to add additional stories to an existing arrivals building. The original foundation system was designed for an allowable bearing capacity of 160 kPa, sufficient for the existing load but inadequate for the proposed vertical extension. Increasing building loads without reinforcing the ground could have compromised structural safety and serviceability.

The structural upgrade required an increase in foundation capacity of up to 100%. Two engineering solutions were considered:

The client opted for the second approach — Geobear’s ground improvement solution— due to its lower cost, shorter programme, and minimal operational impact

Terminal 3 Site

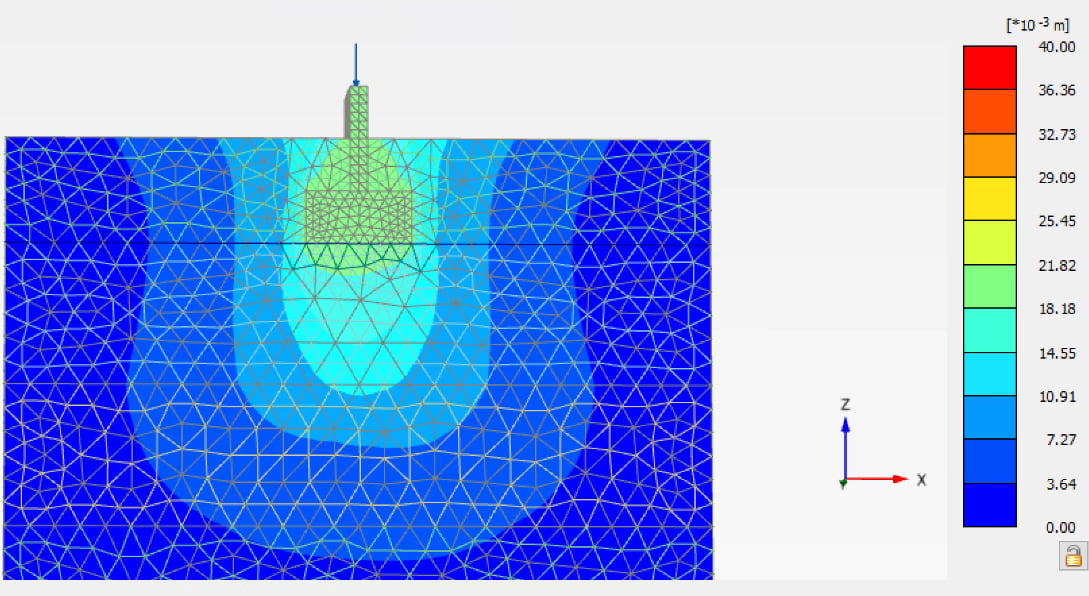

Geobear's in-house design team used PLAXIS software to accurately model and design a solution that met the client’s requirements. We used geopolymer injection to increase the load-bearing capacity of the foundation pads, avoiding the need for excavation. This approach was not only faster but also more sustainable, as it eliminated the need for the disposal of excavated material.

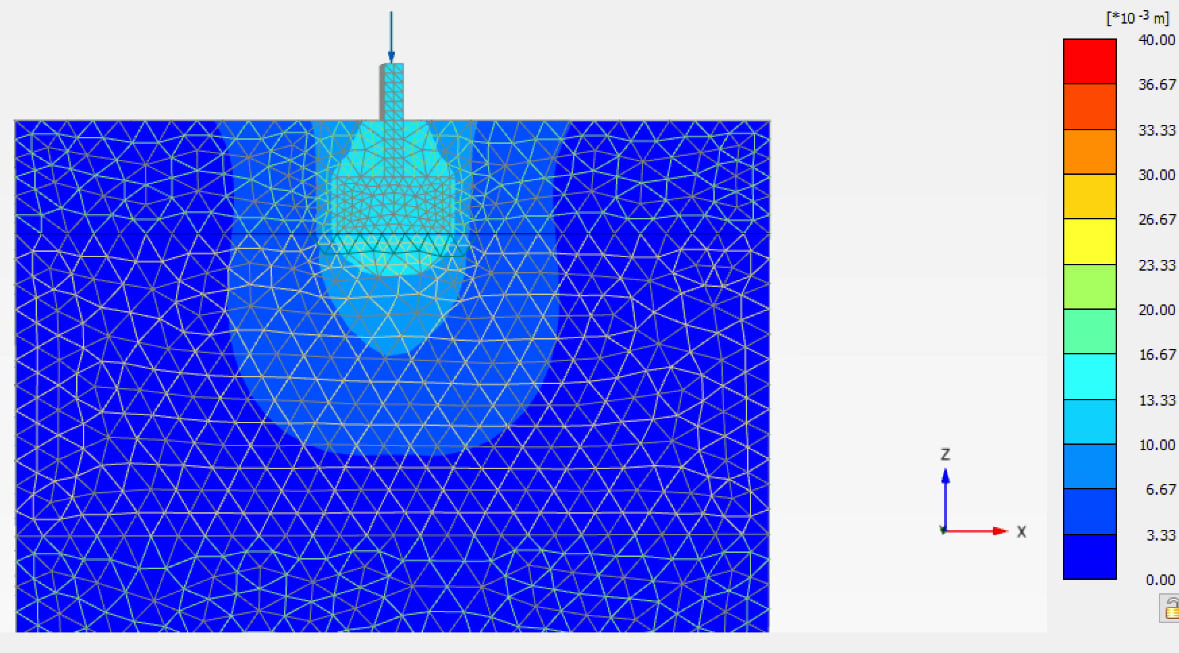

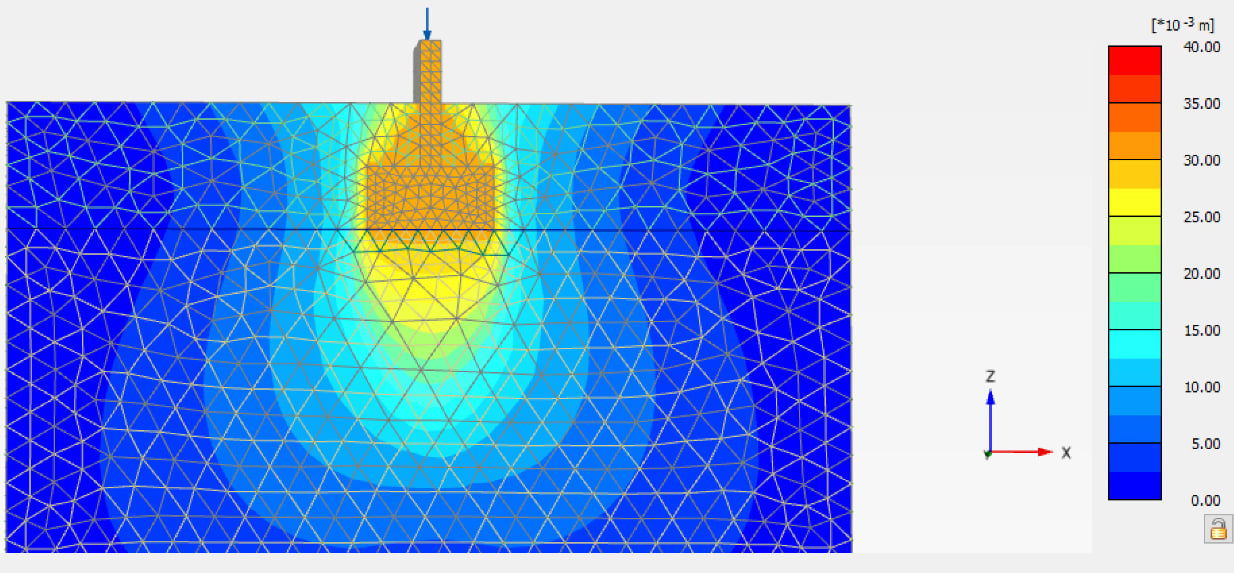

Numerical simulations were performed to assess the impact of load increase and ground treatment:

|

Condition |

Factor of Safety |

Settlement |

|

Original (no load increase) |

2.5 |

11.2 mm |

|

Load increase – no treatment |

1.7 |

31.2 mm |

|

Load increase – with geopolymer treatment |

2.4 |

20.0 mm |

Existing condition

Factor of safety = 2.5

Settlement = 11.2mm

Load increase no treatment

Factor of safety = 1.7

Settlement = 31.2mm

Load increase with treatment

Factor of safety = 2.4

Settlement = 20mm

The full improvement is detailed in the chart below.

| Pad no. | Depth of foundation (m) | Required bearing Pressure (kPa) | Design dosage (kg) | Actual injected dosage (kg) | Current Avg SPT | Achieved Avg SPT | Avg soil modulus before injections (MPa) | Avg soil modulus after injections (MPa) | Settlement after injections after load increase (mm) | Improvement in soil modulus |

|---|---|---|---|---|---|---|---|---|---|---|

| D31 | 1.9 | 275 | 220 | 223 | 7 | 26 | 15.6 | 38.4 | 5.5 | 146% |

| D29 | 1.9 | 275 | 240 | 240 | 2 | 24 | 10.1 | 36 | 5.9 | 257% |

| D27 | 2.5 | 330 | 140 | 141 | 60 | 64 | 79.2 | 84 | 3 | 6% |

| D25 | 2.7 | 280 | 140 | 136 | 25 | 43 | 37.2 | 58.8 | 3.7 | 58% |

| D23 | 1.6 | 275 | 120 | 119 | 23 | 44 | 34.2 | 59.4 | 3.6 | 74% |

| A29 | 3.4 | 330 | 80 | 81 | 13 | 29 | 22.8 | 42 | 6 | 84% |

| A27 | 3.2 | 330 | 100 | 100 | 4 | 39 | 11.5 | 54 | 4.7 | 369% |

| A25 | 2.7 | 319 | 120 | 120 | 33 | 39 | 46.8 | 54 | 4.5 | 15% |

The project was completed successfully within the client's specified timeframe and budget, with no disruption to airport operations. Geobear's solution increased the load-bearing capacity of the foundation pads by required target values for each pad foundation (see table below), providing a solid base for the vertical expansion of the terminal. The use of geopolymer injection also had significant sustainability benefits, reducing the project’s carbon footprint by up to 60%.

"Our project greatly benefited from the professional geotechnical design and execution services provided by Geobear. As structural engineers on this vertical expansion project, the building’s existing foundations needed strengthening. We had initially proposed to increase the area of the existing concrete pad foundations – which was going to be a costly and challenging construction.

After consultations with Geobear’s geotechnical designers and reviewing the existing ground conditions with them, we were able to use one of their innovative solutions – inject grout polymer beneath the existing foundations to support the expansion.

This was a huge success to the project saving cost, time and was more sustainable. Geobear also monitored the building’s movement and assisted the contractor during grouting to eliminate execution error and advise on the extent of grout required.

The end results were very impressive and successful. Throughout the design and construction process Geobear was a pleasure to work with. We would highly recommend them and would like to see their innovative, less invasive solutions used more often."

Steve Pinnegar, C&S Director, BakerHicks

Get in touch with our expert team today and discover how Geobear can extend the life of your critical infrastructure assets.