Rail

Challenge

A newly rebuilt concrete level crossing suffered 60 mm settlement within a year, causing geometry faults, poor ride quality, and ongoing maintenance from weak, peat-rich subgrades.

Solution

Geobear stabilised the crossing using geopolymer injection, lifting slabs to tolerance, restoring stiffness, and extending service life by 22 years — all completed within a single weekend.

Reduction in CO₂ emissions versus full reconstruction

22 years projected life extension before re-treatment

Post-treatment settlement rate (down from 0.3 mm/day)

Concrete level crossings are among the most maintenance-intensive railway assets. Their frequent exposure to dynamic axle loads, poor drainage, and weak subgrades often leads to progressive settlement, loss of geometry, and service-affecting ride quality issues. At the Swineshead Level Crossing in northeast England, settlement of up to 60 mm below design level was recorded less than a year after reconstruction. The cause was attributed to soft peaty soils and inadequate drainage, resulting in geometry deterioration at a rate of 0.3 mm/day.

The conventional remediation approach—complete reconstruction—involves excavation, heavy plant, extensive logistics, and long possessions. This disrupts railway operations, increases embodied carbon, and imposes high costs on asset owners.

A full level-crossing renewal typically uses new precast concrete slabs, ballast, sleepers, and rails. It is labour-intensive and demands long track possessions, usually bank-holiday blockades, with significant waste generation and fuel consumption. Carbon analysis shows that a full reconstruction emits nearly 200 tonnes CO₂e, with over 93% of emissions from raw material production. While this method restores full design geometry and offers a lifespan of 15–20 years, it is expensive, slow, and environmentally inefficient.

Geobear introduced a geopolymer injection system to stabilise the subgrade and lift the slabs back to tolerance without excavation. The technique involves drilling 12 mm holes through the slab and injecting expanding geopolymer resin into the Type 1 sub-base approximately 50 mm below the slab, with slab lift monitored by laser levels. The system achieves a lift within +0 / −10 mm, as per TRK/2102 specifications, restoring design geometry rapidly.

The design focused on improving the stiffness of the sub-base and redistributing stresses through the soft subgrade. Injection points were arranged to ensure uniform coverage beneath the slab and transition zones. The geopolymer resin expands under controlled pressure, compacting voids and weak zones. Injections were executed during two weekend shifts, avoiding full possession.

Instrumentation included laser monitoring of lift, measurement train runs to track post-treatment performance, and differential geometry control to prevent twist faults.

|

Parameter |

Before Treatment |

After (May 2021) |

After (July 2021) |

|

Down line – track quality |

17.6 mm |

5.57 mm |

5.98 mm |

|

Up line – track quality |

20.0 mm |

4.3 mm |

5.0 mm |

|

Vertical geometry fault |

33–35 mm |

9–10 mm |

9–10 mm |

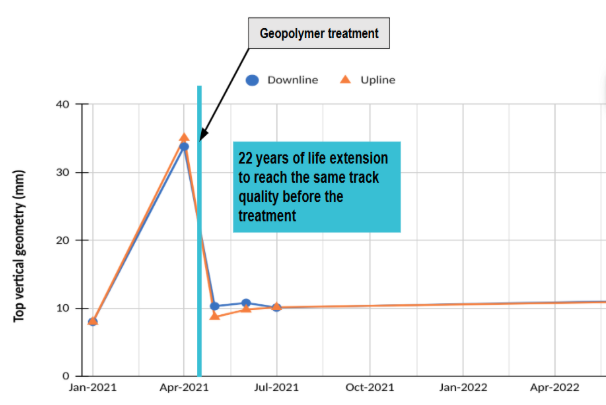

The rate of deterioration dropped from 0.3 mm/day to 0.004 mm/day, implying a 22-year life extension before reaching pre-treatment geometry levels.

A carbon life-cycle assessment compared Geobear’s system with full reconstruction:

|

Metric |

Geopolymer Injection |

Full Reconstruction |

|

Total CO₂e (per intervention) |

3.25 tonnes |

199 tonnes |

|

Reduction vs. conventional |

−95.1% |

— |

|

Required interventions over 60 years |

3 |

1 |

|

Net CO₂e over 60 years |

9.7 tonnes |

199 tonnes |

Even with three interventions over six decades, geopolymer treatment cuts lifetime carbon emissions by 95%. Additionally, installation is 43% cheaper and completed in one weekend rather than during a long blockade.

The Swineshead Level Crossing project confirms that geopolymer injections are a technically sound, sustainable, and economical alternative to full reconstruction. By stabilising the subgrade and restoring geometry quickly, Geobear’s solution has extended asset life by over two decades, reduced carbon footprint by 95%, and delivered measurable gains in network productivity. This innovation provides a model for low-carbon, high-efficiency railway maintenance adaptable across diverse rail infrastructures worldwide.

Get in touch with our expert team today and discover how Geobear can extend the life of your critical infrastructure assets.