Highways

Challenge

Severe subsidence in Glasgow’s Kinfauns Drive exposed extremely soft clays with near-zero shear strength — excavation or piling would have been costly, disruptive, and environmentally unsustainable.

Solution

Geobear used expansive geopolymer injection to fracture and reinforce weak clays, increasing shear strength by 780%, halting settlement, and delivering long-term stability without excavation.

Average improvement in clay shear strength

Subsidence zone fully treated

Up to 640 mm of settlement corrected

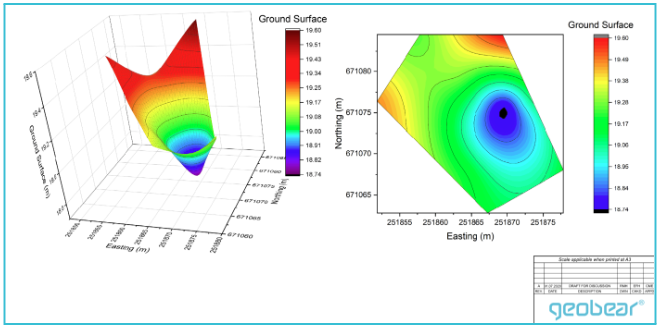

At Kinfauns Drive, Drumchapel (Glasgow), an area of ground approximately 600 m² had suffered significant subsidence. The movement, thought to be associated with leakage from a deeply buried sewer, created a shallow depression up to 640 mm deep.

This depression posed risks for both infrastructure and the local community. Investigations confirmed that the underlying soils were very weak and required engineered ground improvement to arrest further settlement.

The geotechnical challenge at Kinfauns Drive was extreme:

fact

Geobear designed an expansive geopolymer injection programme specifically tailored to soft clays.

The process for the treatment for soft clays is based on fracturing the clays and permeation of geopolymer along the fractures.The pressure required to fracture the clay can be determined using undrained shear strength and overburden pressure.

The length of the fracture can be estimated from fracture toughness and lift/expansion pressure of the geopolymer. The final density of the geopolymer in the cracks controls the strength of the hardened geopolymer.

There is a relationship between the strength of the hardened geopolymer, the mass injected and the relative improvement in shear strength of the soft clay. For this project, Geobear clay treatment targeted a depth between 1.75m and 3.75m e where most improvement was required.

Injection locations were set out at 1.0 m centres on the surface, on the basis of the calculated hydraulic fracture length in the clay. Initial modelling indicated an improvement of shear strength of around 600% should be achievable based on the design.

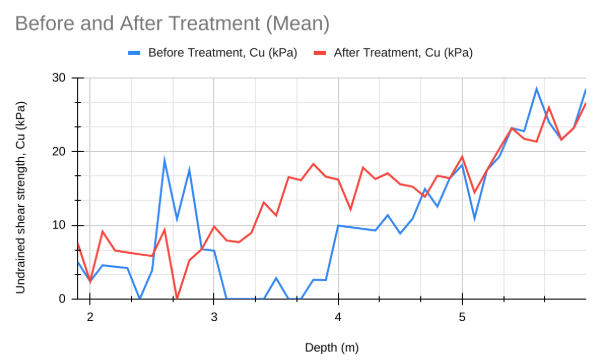

Before and after shear strength:

Post-treatment verification confirmed the success of the works:

Shear strength improvement: From near-zero to 18 kN/m² at the weakest location.

Average increase: 780% improvement across the 1.75–3.75 m treatment zone (exceeding predictions). The measured improvement in shear strength was determined via post treatment DP testing, with blow counts converted to undrained cohesion via the correlations established prior to testing in the site investigation phase, the results are shown on Figure 4.

Depth of effect: Resin was effective up to 1 m below each injection level, providing broad treatment coverage.

Stability achieved: No further settlement has occurred since the works.

Carbon savings: Compared with excavation and replacement, geopolymer injection delivered a fraction of the embodied carbon, with minimal plant or spoil.

Get in touch with our expert team today and discover how Geobear can extend the life of your critical infrastructure assets.